There are 4 different tests that can be done to check the brake magnets on your trailer. The first test you should do is to use a multimeter to check the amperage of your trailer braking system. The trailer brake magnets will draw amperage from the brake controller based on the output voltage sent by the brake controller. Performing this test will let you know if the magnets are functioning properly or if further testing is required.

If further testing is indicated, you can test the individual brake magnets for proper amperage. Test each magnet for a short and test the magnets for resistance. Below we have outlined each of these tests for you.

Testing with Trailer Connected to the Vehicle

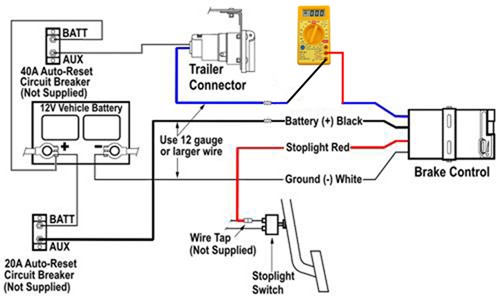

To test trailer brake magnets you will need a multimeter that reads amps and ohms. A good brake controller, like theTekonsha P3, has test functions built in. To test with a multimeter, first you will connect the ammeter inline with the blue wire exiting the back of the brake controller or use the brake controller's diagnostic readings.

Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet or magnets. If the reading is less than the specified amount, the leads are bad and the magnet or magnets should be replaced.

Electromagnet Specifications

10 and 12 Inch Brake Drums

Max Amps at 12-13 Volts

2 Brakes

7.5-8.2

4 Brakes

15.0-16.3

6 Brakes

22.6-24.5

7 inch Diameter Brake Drum

Max Amps at 12-13 Volts

2 Brakes

6.3-6.8

4 Brakes

12.6-13.7

6 Brakes

19.0-20.6

Testing Individual Brake Magnets

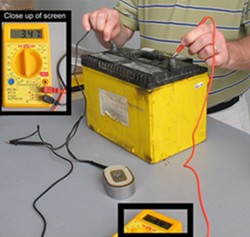

Testing individual brake magnets for proper function can be accomplished by severing the magnet wires and connecting the ammeter between the positive terminal of a 12-volt battery and one of the magnet wires; it does not matter which one. Then connect the other magnet wire to the negative battery terminal. Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet. If the reading is less than the specified amount, the leads are bad and the magnet should be replaced.

Individual Brake Magnet Amperage Specifications

10 and 12 Inch Brake Magnets

7 Inch Brake Magnets

3.2-4.0 Max amps at 12-13 volts

3.0-3.2 Max amps at 12-13 volts

Testing Individual Brake Magnet for a Short

To determine if a brake magnet has an internal short, touch the base of the brake magnet to the negative post of a 12-volt battery. Then, connect one of the brake magnet wires to the negative lead of a multimeter and the positive lead of the multimeter to the positive post of the battery. If any amperage is detected, the magnet is shorted and will need to be replaced.

Testing Brake Magnet Resistance

Further testing can be done with an ohmmeter. Using the ohmmeter function on the multimeter, check the resistance between the brake magnet wires. If the resistance is not within the specified range (see specifications below), then the magnet will need to be replaced.

There are 4 different tests that can be done to check the brake magnets on your trailer. The first test you should do is to use a multimeter to check the amperage of your trailer braking system. The trailer brake magnets will draw amperage from the brake controller based on the output voltage sent by the brake controller. Performing this test will let you know if the magnets are functioning properly or if further testing is required.

If further testing is indicated, you can test the individual brake magnets for proper amperage. Test each magnet for a short and test the magnets for resistance. Below we have outlined each of these tests for you.

Testing with Trailer Connected to the Vehicle

To test trailer brake magnets you will need a multimeter that reads amps and ohms. A good brake controller, like theTekonsha P3, has test functions built in. To test with a multimeter, first you will connect the ammeter inline with the blue wire exiting the back of the brake controller or use the brake controller's diagnostic readings.

Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet or magnets. If the reading is less than the specified amount, the leads are bad and the magnet or magnets should be replaced.

Electromagnet Specifications

10 and 12 Inch Brake Drums

Max Amps at 12-13 Volts

2 Brakes

7.5-8.2

4 Brakes

15.0-16.3

6 Brakes

22.6-24.5

7 inch Diameter Brake Drum

Max Amps at 12-13 Volts

2 Brakes

6.3-6.8

4 Brakes

12.6-13.7

6 Brakes

19.0-20.6

Testing Individual Brake Magnets

Testing individual brake magnets for proper function can be accomplished by severing the magnet wires and connecting the ammeter between the positive terminal of a 12-volt battery and one of the magnet wires; it does not matter which one. Then connect the other magnet wire to the negative battery terminal. Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet. If the reading is less than the specified amount, the leads are bad and the magnet should be replaced.

Individual Brake Magnet Amperage Specifications

10 and 12 Inch Brake Magnets

7 Inch Brake Magnets

3.2-4.0 Max amps at 12-13 volts

3.0-3.2 Max amps at 12-13 volts

Testing Individual Brake Magnet for a Short

To determine if a brake magnet has an internal short, touch the base of the brake magnet to the negative post of a 12-volt battery. Then, connect one of the brake magnet wires to the negative lead of a multimeter and the positive lead of the multimeter to the positive post of the battery. If any amperage is detected, the magnet is shorted and will need to be replaced.

Testing Brake Magnet Resistance

Further testing can be done with an ohmmeter. Using the ohmmeter function on the multimeter, check the resistance between the brake magnet wires. If the resistance is not within the specified range (see specifications below), then the magnet will need to be replaced.

There are 4 different tests that can be done to check the brake magnets on your trailer. The first test you should do is to use a multimeter to check the amperage of your trailer braking system. The trailer brake magnets will draw amperage from the brake controller based on the output voltage sent by the brake controller. Performing this test will let you know if the magnets are functioning properly or if further testing is required.

If further testing is indicated, you can test the individual brake magnets for proper amperage. Test each magnet for a short and test the magnets for resistance. Below we have outlined each of these tests for you.

Testing with Trailer Connected to the Vehicle

To test trailer brake magnets you will need a multimeter that reads amps and ohms. A good brake controller, like theTekonsha P3, has test functions built in. To test with a multimeter, first you will connect the ammeter inline with the blue wire exiting the back of the brake controller or use the brake controller's diagnostic readings.

Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet or magnets. If the reading is less than the specified amount, the leads are bad and the magnet or magnets should be replaced.

Electromagnet Specifications

10 and 12 Inch Brake Drums

Max Amps at 12-13 Volts

2 Brakes

7.5-8.2

4 Brakes

15.0-16.3

6 Brakes

22.6-24.5

7 inch Diameter Brake Drum

Max Amps at 12-13 Volts

2 Brakes

6.3-6.8

4 Brakes

12.6-13.7

6 Brakes

19.0-20.6

Testing Individual Brake Magnets

Testing individual brake magnets for proper function can be accomplished by severing the magnet wires and connecting the ammeter between the positive terminal of a 12-volt battery and one of the magnet wires; it does not matter which one. Then connect the other magnet wire to the negative battery terminal. Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet. If the reading is less than the specified amount, the leads are bad and the magnet should be replaced.

Individual Brake Magnet Amperage Specifications

10 and 12 Inch Brake Magnets

7 Inch Brake Magnets

3.2-4.0 Max amps at 12-13 volts

3.0-3.2 Max amps at 12-13 volts

Testing Individual Brake Magnet for a Short

To determine if a brake magnet has an internal short, touch the base of the brake magnet to the negative post of a 12-volt battery. Then, connect one of the brake magnet wires to the negative lead of a multimeter and the positive lead of the multimeter to the positive post of the battery. If any amperage is detected, the magnet is shorted and will need to be replaced.

Testing Brake Magnet Resistance

Further testing can be done with an ohmmeter. Using the ohmmeter function on the multimeter, check the resistance between the brake magnet wires. If the resistance is not within the specified range (see specifications below), then the magnet will need to be replaced.

There are 4 different tests that can be done to check the brake magnets on your trailer. The first test you should do is to use a multimeter to check the amperage of your trailer braking system. The trailer brake magnets will draw amperage from the brake controller based on the output voltage sent by the brake controller. Performing this test will let you know if the magnets are functioning properly or if further testing is required.

If further testing is indicated, you can test the individual brake magnets for proper amperage. Test each magnet for a short and test the magnets for resistance. Below we have outlined each of these tests for you.

Testing with Trailer Connected to the Vehicle

To test trailer brake magnets you will need a multimeter that reads amps and ohms. A good brake controller, like theTekonsha P3, has test functions built in. To test with a multimeter, first you will connect the ammeter inline with the blue wire exiting the back of the brake controller or use the brake controller's diagnostic readings.

Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet or magnets. If the reading is less than the specified amount, the leads are bad and the magnet or magnets should be replaced.

Electromagnet Specifications

10 and 12 Inch Brake Drums

Max Amps at 12-13 Volts

2 Brakes

7.5-8.2

4 Brakes

15.0-16.3

6 Brakes

22.6-24.5

7 inch Diameter Brake Drum

Max Amps at 12-13 Volts

2 Brakes

6.3-6.8

4 Brakes

12.6-13.7

6 Brakes

19.0-20.6

Testing Individual Brake Magnets

Testing individual brake magnets for proper function can be accomplished by severing the magnet wires and connecting the ammeter between the positive terminal of a 12-volt battery and one of the magnet wires; it does not matter which one. Then connect the other magnet wire to the negative battery terminal. Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet. If the reading is less than the specified amount, the leads are bad and the magnet should be replaced.

Individual Brake Magnet Amperage Specifications

10 and 12 Inch Brake Magnets

7 Inch Brake Magnets

3.2-4.0 Max amps at 12-13 volts

3.0-3.2 Max amps at 12-13 volts

Testing Individual Brake Magnet for a Short

To determine if a brake magnet has an internal short, touch the base of the brake magnet to the negative post of a 12-volt battery. Then, connect one of the brake magnet wires to the negative lead of a multimeter and the positive lead of the multimeter to the positive post of the battery. If any amperage is detected, the magnet is shorted and will need to be replaced.

Testing Brake Magnet Resistance

Further testing can be done with an ohmmeter. Using the ohmmeter function on the multimeter, check the resistance between the brake magnet wires. If the resistance is not within the specified range (see specifications below), then the magnet will need to be replaced.

There are 4 different tests that can be done to check the brake magnets on your trailer. The first test you should do is to use a multimeter to check the amperage of your trailer braking system. The trailer brake magnets will draw amperage from the brake controller based on the output voltage sent by the brake controller. Performing this test will let you know if the magnets are functioning properly or if further testing is required.

If further testing is indicated, you can test the individual brake magnets for proper amperage. Test each magnet for a short and test the magnets for resistance. Below we have outlined each of these tests for you.

Testing with Trailer Connected to the Vehicle

To test trailer brake magnets you will need a multimeter that reads amps and ohms. A good brake controller, like theTekonsha P3, has test functions built in. To test with a multimeter, first you will connect the ammeter inline with the blue wire exiting the back of the brake controller or use the brake controller's diagnostic readings.

Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet or magnets. If the reading is less than the specified amount, the leads are bad and the magnet or magnets should be replaced.

Electromagnet Specifications

10 and 12 Inch Brake Drums

Max Amps at 12-13 Volts

2 Brakes

7.5-8.2

4 Brakes

15.0-16.3

6 Brakes

22.6-24.5

7 inch Diameter Brake Drum

Max Amps at 12-13 Volts

2 Brakes

6.3-6.8

4 Brakes

12.6-13.7

6 Brakes

19.0-20.6

Testing Individual Brake Magnets

Testing individual brake magnets for proper function can be accomplished by severing the magnet wires and connecting the ammeter between the positive terminal of a 12-volt battery and one of the magnet wires; it does not matter which one. Then connect the other magnet wire to the negative battery terminal. Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet. If the reading is less than the specified amount, the leads are bad and the magnet should be replaced.

Individual Brake Magnet Amperage Specifications

10 and 12 Inch Brake Magnets

7 Inch Brake Magnets

3.2-4.0 Max amps at 12-13 volts

3.0-3.2 Max amps at 12-13 volts

Testing Individual Brake Magnet for a Short

To determine if a brake magnet has an internal short, touch the base of the brake magnet to the negative post of a 12-volt battery. Then, connect one of the brake magnet wires to the negative lead of a multimeter and the positive lead of the multimeter to the positive post of the battery. If any amperage is detected, the magnet is shorted and will need to be replaced.

Testing Brake Magnet Resistance

Further testing can be done with an ohmmeter. Using the ohmmeter function on the multimeter, check the resistance between the brake magnet wires. If the resistance is not within the specified range (see specifications below), then the magnet will need to be replaced.

There are 4 different tests that can be done to check the brake magnets on your trailer. The first test you should do is to use a multimeter to check the amperage of your trailer braking system. The trailer brake magnets will draw amperage from the brake controller based on the output voltage sent by the brake controller. Performing this test will let you know if the magnets are functioning properly or if further testing is required.

If further testing is indicated, you can test the individual brake magnets for proper amperage. Test each magnet for a short and test the magnets for resistance. Below we have outlined each of these tests for you.

Testing with Trailer Connected to the Vehicle

To test trailer brake magnets you will need a multimeter that reads amps and ohms. A good brake controller, like theTekonsha P3, has test functions built in. To test with a multimeter, first you will connect the ammeter inline with the blue wire exiting the back of the brake controller or use the brake controller's diagnostic readings.

Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet or magnets. If the reading is less than the specified amount, the leads are bad and the magnet or magnets should be replaced.

Electromagnet Specifications

10 and 12 Inch Brake Drums

Max Amps at 12-13 Volts

2 Brakes

7.5-8.2

4 Brakes

15.0-16.3

6 Brakes

22.6-24.5

7 inch Diameter Brake Drum

Max Amps at 12-13 Volts

2 Brakes

6.3-6.8

4 Brakes

12.6-13.7

6 Brakes

19.0-20.6

Testing Individual Brake Magnets

Testing individual brake magnets for proper function can be accomplished by severing the magnet wires and connecting the ammeter between the positive terminal of a 12-volt battery and one of the magnet wires; it does not matter which one. Then connect the other magnet wire to the negative battery terminal. Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet. If the reading is less than the specified amount, the leads are bad and the magnet should be replaced.

Individual Brake Magnet Amperage Specifications

10 and 12 Inch Brake Magnets

7 Inch Brake Magnets

3.2-4.0 Max amps at 12-13 volts

3.0-3.2 Max amps at 12-13 volts

Testing Individual Brake Magnet for a Short

To determine if a brake magnet has an internal short, touch the base of the brake magnet to the negative post of a 12-volt battery. Then, connect one of the brake magnet wires to the negative lead of a multimeter and the positive lead of the multimeter to the positive post of the battery. If any amperage is detected, the magnet is shorted and will need to be replaced.

Testing Brake Magnet Resistance

Further testing can be done with an ohmmeter. Using the ohmmeter function on the multimeter, check the resistance between the brake magnet wires. If the resistance is not within the specified range (see specifications below), then the magnet will need to be replaced.

There are 4 different tests that can be done to check the brake magnets on your trailer. The first test you should do is to use a multimeter to check the amperage of your trailer braking system. The trailer brake magnets will draw amperage from the brake controller based on the output voltage sent by the brake controller. Performing this test will let you know if the magnets are functioning properly or if further testing is required.

If further testing is indicated, you can test the individual brake magnets for proper amperage. Test each magnet for a short and test the magnets for resistance. Below we have outlined each of these tests for you.

Testing with Trailer Connected to the Vehicle

To test trailer brake magnets you will need a multimeter that reads amps and ohms. A good brake controller, like theTekonsha P3, has test functions built in. To test with a multimeter, first you will connect the ammeter inline with the blue wire exiting the back of the brake controller or use the brake controller's diagnostic readings.

Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet or magnets. If the reading is less than the specified amount, the leads are bad and the magnet or magnets should be replaced.

Electromagnet Specifications

10 and 12 Inch Brake Drums

Max Amps at 12-13 Volts

2 Brakes

7.5-8.2

4 Brakes

15.0-16.3

6 Brakes

22.6-24.5

7 inch Diameter Brake Drum

Max Amps at 12-13 Volts

2 Brakes

6.3-6.8

4 Brakes

12.6-13.7

6 Brakes

19.0-20.6

Testing Individual Brake Magnets

Testing individual brake magnets for proper function can be accomplished by severing the magnet wires and connecting the ammeter between the positive terminal of a 12-volt battery and one of the magnet wires; it does not matter which one. Then connect the other magnet wire to the negative battery terminal. Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet. If the reading is less than the specified amount, the leads are bad and the magnet should be replaced.

Individual Brake Magnet Amperage Specifications

10 and 12 Inch Brake Magnets

7 Inch Brake Magnets

3.2-4.0 Max amps at 12-13 volts

3.0-3.2 Max amps at 12-13 volts

Testing Individual Brake Magnet for a Short

To determine if a brake magnet has an internal short, touch the base of the brake magnet to the negative post of a 12-volt battery. Then, connect one of the brake magnet wires to the negative lead of a multimeter and the positive lead of the multimeter to the positive post of the battery. If any amperage is detected, the magnet is shorted and will need to be replaced.

Testing Brake Magnet Resistance

Further testing can be done with an ohmmeter. Using the ohmmeter function on the multimeter, check the resistance between the brake magnet wires. If the resistance is not within the specified range (see specifications below), then the magnet will need to be replaced.

There are 4 different tests that can be done to check the brake magnets on your trailer. The first test you should do is to use a multimeter to check the amperage of your trailer braking system. The trailer brake magnets will draw amperage from the brake controller based on the output voltage sent by the brake controller. Performing this test will let you know if the magnets are functioning properly or if further testing is required.

If further testing is indicated, you can test the individual brake magnets for proper amperage. Test each magnet for a short and test the magnets for resistance. Below we have outlined each of these tests for you.

Testing with Trailer Connected to the Vehicle

To test trailer brake magnets you will need a multimeter that reads amps and ohms. A good brake controller, like theTekonsha P3, has test functions built in. To test with a multimeter, first you will connect the ammeter inline with the blue wire exiting the back of the brake controller or use the brake controller's diagnostic readings.

Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet or magnets. If the reading is less than the specified amount, the leads are bad and the magnet or magnets should be replaced.

Electromagnet Specifications

10 and 12 Inch Brake Drums

Max Amps at 12-13 Volts

2 Brakes

7.5-8.2

4 Brakes

15.0-16.3

6 Brakes

22.6-24.5

7 inch Diameter Brake Drum

Max Amps at 12-13 Volts

2 Brakes

6.3-6.8

4 Brakes

12.6-13.7

6 Brakes

19.0-20.6

Testing Individual Brake Magnets

Testing individual brake magnets for proper function can be accomplished by severing the magnet wires and connecting the ammeter between the positive terminal of a 12-volt battery and one of the magnet wires; it does not matter which one. Then connect the other magnet wire to the negative battery terminal. Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet. If the reading is less than the specified amount, the leads are bad and the magnet should be replaced.

Individual Brake Magnet Amperage Specifications

10 and 12 Inch Brake Magnets

7 Inch Brake Magnets

3.2-4.0 Max amps at 12-13 volts

3.0-3.2 Max amps at 12-13 volts

Testing Individual Brake Magnet for a Short

To determine if a brake magnet has an internal short, touch the base of the brake magnet to the negative post of a 12-volt battery. Then, connect one of the brake magnet wires to the negative lead of a multimeter and the positive lead of the multimeter to the positive post of the battery. If any amperage is detected, the magnet is shorted and will need to be replaced.

Testing Brake Magnet Resistance

Further testing can be done with an ohmmeter. Using the ohmmeter function on the multimeter, check the resistance between the brake magnet wires. If the resistance is not within the specified range (see specifications below), then the magnet will need to be replaced.

There are 4 different tests that can be done to check the brake magnets on your trailer. The first test you should do is to use a multimeter to check the amperage of your trailer braking system. The trailer brake magnets will draw amperage from the brake controller based on the output voltage sent by the brake controller. Performing this test will let you know if the magnets are functioning properly or if further testing is required.

If further testing is indicated, you can test the individual brake magnets for proper amperage. Test each magnet for a short and test the magnets for resistance. Below we have outlined each of these tests for you.

Testing with Trailer Connected to the Vehicle

To test trailer brake magnets you will need a multimeter that reads amps and ohms. A good brake controller, like theTekonsha P3, has test functions built in. To test with a multimeter, first you will connect the ammeter inline with the blue wire exiting the back of the brake controller or use the brake controller's diagnostic readings.

Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet or magnets. If the reading is less than the specified amount, the leads are bad and the magnet or magnets should be replaced.

Electromagnet Specifications

10 and 12 Inch Brake Drums

Max Amps at 12-13 Volts

2 Brakes

7.5-8.2

4 Brakes

15.0-16.3

6 Brakes

22.6-24.5

7 inch Diameter Brake Drum

Max Amps at 12-13 Volts

2 Brakes

6.3-6.8

4 Brakes

12.6-13.7

6 Brakes

19.0-20.6

Testing Individual Brake Magnets

Testing individual brake magnets for proper function can be accomplished by severing the magnet wires and connecting the ammeter between the positive terminal of a 12-volt battery and one of the magnet wires; it does not matter which one. Then connect the other magnet wire to the negative battery terminal. Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet. If the reading is less than the specified amount, the leads are bad and the magnet should be replaced.

Individual Brake Magnet Amperage Specifications

10 and 12 Inch Brake Magnets

7 Inch Brake Magnets

3.2-4.0 Max amps at 12-13 volts

3.0-3.2 Max amps at 12-13 volts

Testing Individual Brake Magnet for a Short

To determine if a brake magnet has an internal short, touch the base of the brake magnet to the negative post of a 12-volt battery. Then, connect one of the brake magnet wires to the negative lead of a multimeter and the positive lead of the multimeter to the positive post of the battery. If any amperage is detected, the magnet is shorted and will need to be replaced.

Testing Brake Magnet Resistance

Further testing can be done with an ohmmeter. Using the ohmmeter function on the multimeter, check the resistance between the brake magnet wires. If the resistance is not within the specified range (see specifications below), then the magnet will need to be replaced.

There are 4 different tests that can be done to check the brake magnets on your trailer. The first test you should do is to use a multimeter to check the amperage of your trailer braking system. The trailer brake magnets will draw amperage from the brake controller based on the output voltage sent by the brake controller. Performing this test will let you know if the magnets are functioning properly or if further testing is required.

If further testing is indicated, you can test the individual brake magnets for proper amperage. Test each magnet for a short and test the magnets for resistance. Below we have outlined each of these tests for you.

Testing with Trailer Connected to the Vehicle

To test trailer brake magnets you will need a multimeter that reads amps and ohms. A good brake controller, like theTekonsha P3, has test functions built in. To test with a multimeter, first you will connect the ammeter inline with the blue wire exiting the back of the brake controller or use the brake controller's diagnostic readings.

Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet or magnets. If the reading is less than the specified amount, the leads are bad and the magnet or magnets should be replaced.

Electromagnet Specifications

10 and 12 Inch Brake Drums

Max Amps at 12-13 Volts

2 Brakes

7.5-8.2

4 Brakes

15.0-16.3

6 Brakes

22.6-24.5

7 inch Diameter Brake Drum

Max Amps at 12-13 Volts

2 Brakes

6.3-6.8

4 Brakes

12.6-13.7

6 Brakes

19.0-20.6

Testing Individual Brake Magnets

Testing individual brake magnets for proper function can be accomplished by severing the magnet wires and connecting the ammeter between the positive terminal of a 12-volt battery and one of the magnet wires; it does not matter which one. Then connect the other magnet wire to the negative battery terminal. Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet. If the reading is less than the specified amount, the leads are bad and the magnet should be replaced.

Individual Brake Magnet Amperage Specifications

10 and 12 Inch Brake Magnets

7 Inch Brake Magnets

3.2-4.0 Max amps at 12-13 volts

3.0-3.2 Max amps at 12-13 volts

Testing Individual Brake Magnet for a Short

To determine if a brake magnet has an internal short, touch the base of the brake magnet to the negative post of a 12-volt battery. Then, connect one of the brake magnet wires to the negative lead of a multimeter and the positive lead of the multimeter to the positive post of the battery. If any amperage is detected, the magnet is shorted and will need to be replaced.

Testing Brake Magnet Resistance

Further testing can be done with an ohmmeter. Using the ohmmeter function on the multimeter, check the resistance between the brake magnet wires. If the resistance is not within the specified range (see specifications below), then the magnet will need to be replaced.

There are 4 different tests that can be done to check the brake magnets on your trailer. The first test you should do is to use a multimeter to check the amperage of your trailer braking system. The trailer brake magnets will draw amperage from the brake controller based on the output voltage sent by the brake controller. Performing this test will let you know if the magnets are functioning properly or if further testing is required. If further testing is indicated, you can test the individual brake magnets for proper amperage. Test each magnet for a short and test the magnets for resistance. Below we have outlined each of these tests for you.

Testing with Trailer Connected to the Vehicle

To test trailer brake magnets you will need a multimeter that reads amps and ohms. A good brake controller, like theTekonsha P3, has test functions built in. To test with a multimeter, first you will connect the ammeter inline with the blue wire exiting the back of the brake controller or use the brake controller's diagnostic readings. Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet or magnets. If the reading is less than the specified amount, the leads are bad and the magnet or magnets should be replaced.

Electromagnet Specifications

10 and 12 Inch Brake DrumsMax Amps at 12-13 Volts2 Brakes7.5-8.24 Brakes15.0-16.36 Brakes22.6-24.5 7 inch Diameter Brake DrumMax Amps at 12-13 Volts2 Brakes6.3-6.84 Brakes12.6-13.76 Brakes19.0-20.6

Testing Individual Brake Magnets

Testing individual brake magnets for proper function can be accomplished by severing the magnet wires and connecting the ammeter between the positive terminal of a 12-volt battery and one of the magnet wires; it does not matter which one. Then connect the other magnet wire to the negative battery terminal. Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet. If the reading is less than the specified amount, the leads are bad and the magnet should be replaced.

Individual Brake Magnet Amperage Specifications

10 and 12 Inch Brake Magnets7 Inch Brake Magnets3.2-4.0 Max amps at 12-13 volts3.0-3.2 Max amps at 12-13 volts

Testing Individual Brake Magnet for a Short

To determine if a brake magnet has an internal short, touch the base of the brake magnet to the negative post of a 12-volt battery. Then, connect one of the brake magnet wires to the negative lead of a multimeter and the positive lead of the multimeter to the positive post of the battery. If any amperage is detected, the magnet is shorted and will need to be replaced.

Testing Brake Magnet Resistance

Further testing can be done with an ohmmeter. Using the ohmmeter function on the multimeter, check the resistance between the brake magnet wires. If the resistance is not within the specified range (see specifications below), then the magnet will need to be replaced.

Brake Magnet Resistance Specifications

10 and 12 Inch Brake Magnets7 Inch Brake Magnets3.0-3.8 Ohms3.8-4.0 Ohms

Comments

Paul

Testing Trailer Brake Magnets for Proper Function

There are 4 different tests that can be done to check the brake magnets on your trailer. The first test you should do is to use a multimeter to check the amperage of your trailer braking system. The trailer brake magnets will draw amperage from the brake controller based on the output voltage sent by the brake controller. Performing this test will let you know if the magnets are functioning properly or if further testing is required.

If further testing is indicated, you can test the individual brake magnets for proper amperage. Test each magnet for a short and test the magnets for resistance. Below we have outlined each of these tests for you.

Testing with Trailer Connected to the Vehicle

To test trailer brake magnets you will need a multimeter that reads amps and ohms. A good brake controller, like theTekonsha P3, has test functions built in. To test with a multimeter, first you will connect the ammeter inline with the blue wire exiting the back of the brake controller or use the brake controller's diagnostic readings.

Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet or magnets. If the reading is less than the specified amount, the leads are bad and the magnet or magnets should be replaced.

Electromagnet Specifications

Testing Individual Brake Magnets

Testing individual brake magnets for proper function can be accomplished by severing the magnet wires and connecting the ammeter between the positive terminal of a 12-volt battery and one of the magnet wires; it does not matter which one. Then connect the other magnet wire to the negative battery terminal. Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet. If the reading is less than the specified amount, the leads are bad and the magnet should be replaced.

Individual Brake Magnet Amperage Specifications

Testing Individual Brake Magnet for a Short

To determine if a brake magnet has an internal short, touch the base of the brake magnet to the negative post of a 12-volt battery. Then, connect one of the brake magnet wires to the negative lead of a multimeter and the positive lead of the multimeter to the positive post of the battery. If any amperage is detected, the magnet is shorted and will need to be replaced.

Testing Brake Magnet Resistance

Further testing can be done with an ohmmeter. Using the ohmmeter function on the multimeter, check the resistance between the brake magnet wires. If the resistance is not within the specified range (see specifications below), then the magnet will need to be replaced.

Brake Magnet Resistance Specifications

Paul

Testing Trailer Brake Magnets for Proper Function

There are 4 different tests that can be done to check the brake magnets on your trailer. The first test you should do is to use a multimeter to check the amperage of your trailer braking system. The trailer brake magnets will draw amperage from the brake controller based on the output voltage sent by the brake controller. Performing this test will let you know if the magnets are functioning properly or if further testing is required.

If further testing is indicated, you can test the individual brake magnets for proper amperage. Test each magnet for a short and test the magnets for resistance. Below we have outlined each of these tests for you.

Testing with Trailer Connected to the Vehicle

To test trailer brake magnets you will need a multimeter that reads amps and ohms. A good brake controller, like theTekonsha P3, has test functions built in. To test with a multimeter, first you will connect the ammeter inline with the blue wire exiting the back of the brake controller or use the brake controller's diagnostic readings.

Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet or magnets. If the reading is less than the specified amount, the leads are bad and the magnet or magnets should be replaced.

Electromagnet Specifications

Testing Individual Brake Magnets

Testing individual brake magnets for proper function can be accomplished by severing the magnet wires and connecting the ammeter between the positive terminal of a 12-volt battery and one of the magnet wires; it does not matter which one. Then connect the other magnet wire to the negative battery terminal. Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet. If the reading is less than the specified amount, the leads are bad and the magnet should be replaced.

Individual Brake Magnet Amperage Specifications

Testing Individual Brake Magnet for a Short

To determine if a brake magnet has an internal short, touch the base of the brake magnet to the negative post of a 12-volt battery. Then, connect one of the brake magnet wires to the negative lead of a multimeter and the positive lead of the multimeter to the positive post of the battery. If any amperage is detected, the magnet is shorted and will need to be replaced.

Testing Brake Magnet Resistance

Further testing can be done with an ohmmeter. Using the ohmmeter function on the multimeter, check the resistance between the brake magnet wires. If the resistance is not within the specified range (see specifications below), then the magnet will need to be replaced.

Brake Magnet Resistance Specifications

Testing Trailer Brake Magnets for Proper Function

There are 4 different tests that can be done to check the brake magnets on your trailer. The first test you should do is to use a multimeter to check the amperage of your trailer braking system. The trailer brake magnets will draw amperage from the brake controller based on the output voltage sent by the brake controller. Performing this test will let you know if the magnets are functioning properly or if further testing is required.

If further testing is indicated, you can test the individual brake magnets for proper amperage. Test each magnet for a short and test the magnets for resistance. Below we have outlined each of these tests for you.

Testing with Trailer Connected to the Vehicle

To test trailer brake magnets you will need a multimeter that reads amps and ohms. A good brake controller, like theTekonsha P3, has test functions built in. To test with a multimeter, first you will connect the ammeter inline with the blue wire exiting the back of the brake controller or use the brake controller's diagnostic readings.

Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet or magnets. If the reading is less than the specified amount, the leads are bad and the magnet or magnets should be replaced.

Electromagnet Specifications

Testing Individual Brake Magnets

Testing individual brake magnets for proper function can be accomplished by severing the magnet wires and connecting the ammeter between the positive terminal of a 12-volt battery and one of the magnet wires; it does not matter which one. Then connect the other magnet wire to the negative battery terminal. Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet. If the reading is less than the specified amount, the leads are bad and the magnet should be replaced.

Individual Brake Magnet Amperage Specifications

Testing Individual Brake Magnet for a Short

To determine if a brake magnet has an internal short, touch the base of the brake magnet to the negative post of a 12-volt battery. Then, connect one of the brake magnet wires to the negative lead of a multimeter and the positive lead of the multimeter to the positive post of the battery. If any amperage is detected, the magnet is shorted and will need to be replaced.

Testing Brake Magnet Resistance

Further testing can be done with an ohmmeter. Using the ohmmeter function on the multimeter, check the resistance between the brake magnet wires. If the resistance is not within the specified range (see specifications below), then the magnet will need to be replaced.

Brake Magnet Resistance Specifications

Testing Trailer Brake Magnets for Proper Function

There are 4 different tests that can be done to check the brake magnets on your trailer. The first test you should do is to use a multimeter to check the amperage of your trailer braking system. The trailer brake magnets will draw amperage from the brake controller based on the output voltage sent by the brake controller. Performing this test will let you know if the magnets are functioning properly or if further testing is required.

If further testing is indicated, you can test the individual brake magnets for proper amperage. Test each magnet for a short and test the magnets for resistance. Below we have outlined each of these tests for you.

Testing with Trailer Connected to the Vehicle

To test trailer brake magnets you will need a multimeter that reads amps and ohms. A good brake controller, like theTekonsha P3, has test functions built in. To test with a multimeter, first you will connect the ammeter inline with the blue wire exiting the back of the brake controller or use the brake controller's diagnostic readings.

Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet or magnets. If the reading is less than the specified amount, the leads are bad and the magnet or magnets should be replaced.

Electromagnet Specifications

Testing Individual Brake Magnets

Testing individual brake magnets for proper function can be accomplished by severing the magnet wires and connecting the ammeter between the positive terminal of a 12-volt battery and one of the magnet wires; it does not matter which one. Then connect the other magnet wire to the negative battery terminal. Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet. If the reading is less than the specified amount, the leads are bad and the magnet should be replaced.

Individual Brake Magnet Amperage Specifications

Testing Individual Brake Magnet for a Short

To determine if a brake magnet has an internal short, touch the base of the brake magnet to the negative post of a 12-volt battery. Then, connect one of the brake magnet wires to the negative lead of a multimeter and the positive lead of the multimeter to the positive post of the battery. If any amperage is detected, the magnet is shorted and will need to be replaced.

Testing Brake Magnet Resistance

Further testing can be done with an ohmmeter. Using the ohmmeter function on the multimeter, check the resistance between the brake magnet wires. If the resistance is not within the specified range (see specifications below), then the magnet will need to be replaced.

Brake Magnet Resistance Specifications

Testing Trailer Brake Magnets for Proper Function

There are 4 different tests that can be done to check the brake magnets on your trailer. The first test you should do is to use a multimeter to check the amperage of your trailer braking system. The trailer brake magnets will draw amperage from the brake controller based on the output voltage sent by the brake controller. Performing this test will let you know if the magnets are functioning properly or if further testing is required.

If further testing is indicated, you can test the individual brake magnets for proper amperage. Test each magnet for a short and test the magnets for resistance. Below we have outlined each of these tests for you.

Testing with Trailer Connected to the Vehicle

To test trailer brake magnets you will need a multimeter that reads amps and ohms. A good brake controller, like theTekonsha P3, has test functions built in. To test with a multimeter, first you will connect the ammeter inline with the blue wire exiting the back of the brake controller or use the brake controller's diagnostic readings.

Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet or magnets. If the reading is less than the specified amount, the leads are bad and the magnet or magnets should be replaced.

Electromagnet Specifications

Testing Individual Brake Magnets

Testing individual brake magnets for proper function can be accomplished by severing the magnet wires and connecting the ammeter between the positive terminal of a 12-volt battery and one of the magnet wires; it does not matter which one. Then connect the other magnet wire to the negative battery terminal. Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet. If the reading is less than the specified amount, the leads are bad and the magnet should be replaced.

Individual Brake Magnet Amperage Specifications

Testing Individual Brake Magnet for a Short

To determine if a brake magnet has an internal short, touch the base of the brake magnet to the negative post of a 12-volt battery. Then, connect one of the brake magnet wires to the negative lead of a multimeter and the positive lead of the multimeter to the positive post of the battery. If any amperage is detected, the magnet is shorted and will need to be replaced.

Testing Brake Magnet Resistance

Further testing can be done with an ohmmeter. Using the ohmmeter function on the multimeter, check the resistance between the brake magnet wires. If the resistance is not within the specified range (see specifications below), then the magnet will need to be replaced.

Brake Magnet Resistance Specifications

Testing Trailer Brake Magnets for Proper Function

There are 4 different tests that can be done to check the brake magnets on your trailer. The first test you should do is to use a multimeter to check the amperage of your trailer braking system. The trailer brake magnets will draw amperage from the brake controller based on the output voltage sent by the brake controller. Performing this test will let you know if the magnets are functioning properly or if further testing is required.

If further testing is indicated, you can test the individual brake magnets for proper amperage. Test each magnet for a short and test the magnets for resistance. Below we have outlined each of these tests for you.

Testing with Trailer Connected to the Vehicle

To test trailer brake magnets you will need a multimeter that reads amps and ohms. A good brake controller, like theTekonsha P3, has test functions built in. To test with a multimeter, first you will connect the ammeter inline with the blue wire exiting the back of the brake controller or use the brake controller's diagnostic readings.

Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet or magnets. If the reading is less than the specified amount, the leads are bad and the magnet or magnets should be replaced.

Electromagnet Specifications

Testing Individual Brake Magnets

Testing individual brake magnets for proper function can be accomplished by severing the magnet wires and connecting the ammeter between the positive terminal of a 12-volt battery and one of the magnet wires; it does not matter which one. Then connect the other magnet wire to the negative battery terminal. Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet. If the reading is less than the specified amount, the leads are bad and the magnet should be replaced.

Individual Brake Magnet Amperage Specifications

Testing Individual Brake Magnet for a Short

To determine if a brake magnet has an internal short, touch the base of the brake magnet to the negative post of a 12-volt battery. Then, connect one of the brake magnet wires to the negative lead of a multimeter and the positive lead of the multimeter to the positive post of the battery. If any amperage is detected, the magnet is shorted and will need to be replaced.

Testing Brake Magnet Resistance

Further testing can be done with an ohmmeter. Using the ohmmeter function on the multimeter, check the resistance between the brake magnet wires. If the resistance is not within the specified range (see specifications below), then the magnet will need to be replaced.

Brake Magnet Resistance Specifications

Testing Trailer Brake Magnets for Proper Function

There are 4 different tests that can be done to check the brake magnets on your trailer. The first test you should do is to use a multimeter to check the amperage of your trailer braking system. The trailer brake magnets will draw amperage from the brake controller based on the output voltage sent by the brake controller. Performing this test will let you know if the magnets are functioning properly or if further testing is required.

If further testing is indicated, you can test the individual brake magnets for proper amperage. Test each magnet for a short and test the magnets for resistance. Below we have outlined each of these tests for you.

Testing with Trailer Connected to the Vehicle

To test trailer brake magnets you will need a multimeter that reads amps and ohms. A good brake controller, like theTekonsha P3, has test functions built in. To test with a multimeter, first you will connect the ammeter inline with the blue wire exiting the back of the brake controller or use the brake controller's diagnostic readings.

Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet or magnets. If the reading is less than the specified amount, the leads are bad and the magnet or magnets should be replaced.

Electromagnet Specifications

Testing Individual Brake Magnets

Testing individual brake magnets for proper function can be accomplished by severing the magnet wires and connecting the ammeter between the positive terminal of a 12-volt battery and one of the magnet wires; it does not matter which one. Then connect the other magnet wire to the negative battery terminal. Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet. If the reading is less than the specified amount, the leads are bad and the magnet should be replaced.

Individual Brake Magnet Amperage Specifications

Testing Individual Brake Magnet for a Short

To determine if a brake magnet has an internal short, touch the base of the brake magnet to the negative post of a 12-volt battery. Then, connect one of the brake magnet wires to the negative lead of a multimeter and the positive lead of the multimeter to the positive post of the battery. If any amperage is detected, the magnet is shorted and will need to be replaced.

Testing Brake Magnet Resistance

Further testing can be done with an ohmmeter. Using the ohmmeter function on the multimeter, check the resistance between the brake magnet wires. If the resistance is not within the specified range (see specifications below), then the magnet will need to be replaced.

Brake Magnet Resistance Specifications

Testing Trailer Brake Magnets for Proper Function

There are 4 different tests that can be done to check the brake magnets on your trailer. The first test you should do is to use a multimeter to check the amperage of your trailer braking system. The trailer brake magnets will draw amperage from the brake controller based on the output voltage sent by the brake controller. Performing this test will let you know if the magnets are functioning properly or if further testing is required.

If further testing is indicated, you can test the individual brake magnets for proper amperage. Test each magnet for a short and test the magnets for resistance. Below we have outlined each of these tests for you.

Testing with Trailer Connected to the Vehicle

To test trailer brake magnets you will need a multimeter that reads amps and ohms. A good brake controller, like theTekonsha P3, has test functions built in. To test with a multimeter, first you will connect the ammeter inline with the blue wire exiting the back of the brake controller or use the brake controller's diagnostic readings.

Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet or magnets. If the reading is less than the specified amount, the leads are bad and the magnet or magnets should be replaced.

Electromagnet Specifications

Testing Individual Brake Magnets

Testing individual brake magnets for proper function can be accomplished by severing the magnet wires and connecting the ammeter between the positive terminal of a 12-volt battery and one of the magnet wires; it does not matter which one. Then connect the other magnet wire to the negative battery terminal. Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet. If the reading is less than the specified amount, the leads are bad and the magnet should be replaced.

Individual Brake Magnet Amperage Specifications

Testing Individual Brake Magnet for a Short

To determine if a brake magnet has an internal short, touch the base of the brake magnet to the negative post of a 12-volt battery. Then, connect one of the brake magnet wires to the negative lead of a multimeter and the positive lead of the multimeter to the positive post of the battery. If any amperage is detected, the magnet is shorted and will need to be replaced.

Testing Brake Magnet Resistance

Further testing can be done with an ohmmeter. Using the ohmmeter function on the multimeter, check the resistance between the brake magnet wires. If the resistance is not within the specified range (see specifications below), then the magnet will need to be replaced.

Brake Magnet Resistance Specifications

There are 4 different tests that can be done to check the brake magnets on your trailer. The first test you should do is to use a multimeter to check the amperage of your trailer braking system. The trailer brake magnets will draw amperage from the brake controller based on the output voltage sent by the brake controller. Performing this test will let you know if the magnets are functioning properly or if further testing is required.

If further testing is indicated, you can test the individual brake magnets for proper amperage. Test each magnet for a short and test the magnets for resistance. Below we have outlined each of these tests for you.

Testing with Trailer Connected to the Vehicle

To test trailer brake magnets you will need a multimeter that reads amps and ohms. A good brake controller, like theTekonsha P3, has test functions built in. To test with a multimeter, first you will connect the ammeter inline with the blue wire exiting the back of the brake controller or use the brake controller's diagnostic readings.

Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet or magnets. If the reading is less than the specified amount, the leads are bad and the magnet or magnets should be replaced.

Electromagnet Specifications

Testing Individual Brake Magnets

Testing individual brake magnets for proper function can be accomplished by severing the magnet wires and connecting the ammeter between the positive terminal of a 12-volt battery and one of the magnet wires; it does not matter which one. Then connect the other magnet wire to the negative battery terminal. Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet. If the reading is less than the specified amount, the leads are bad and the magnet should be replaced.

Individual Brake Magnet Amperage Specifications

Testing Individual Brake Magnet for a Short

To determine if a brake magnet has an internal short, touch the base of the brake magnet to the negative post of a 12-volt battery. Then, connect one of the brake magnet wires to the negative lead of a multimeter and the positive lead of the multimeter to the positive post of the battery. If any amperage is detected, the magnet is shorted and will need to be replaced.

Testing Brake Magnet Resistance

Further testing can be done with an ohmmeter. Using the ohmmeter function on the multimeter, check the resistance between the brake magnet wires. If the resistance is not within the specified range (see specifications below), then the magnet will need to be replaced.

Brake Magnet Resistance Specifications

Testing Trailer Brake Magnets for Proper Function

There are 4 different tests that can be done to check the brake magnets on your trailer. The first test you should do is to use a multimeter to check the amperage of your trailer braking system. The trailer brake magnets will draw amperage from the brake controller based on the output voltage sent by the brake controller. Performing this test will let you know if the magnets are functioning properly or if further testing is required.

If further testing is indicated, you can test the individual brake magnets for proper amperage. Test each magnet for a short and test the magnets for resistance. Below we have outlined each of these tests for you.

Testing with Trailer Connected to the Vehicle

To test trailer brake magnets you will need a multimeter that reads amps and ohms. A good brake controller, like theTekonsha P3, has test functions built in. To test with a multimeter, first you will connect the ammeter inline with the blue wire exiting the back of the brake controller or use the brake controller's diagnostic readings.

Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet or magnets. If the reading is less than the specified amount, the leads are bad and the magnet or magnets should be replaced.

Electromagnet Specifications

Testing Individual Brake Magnets

Testing individual brake magnets for proper function can be accomplished by severing the magnet wires and connecting the ammeter between the positive terminal of a 12-volt battery and one of the magnet wires; it does not matter which one. Then connect the other magnet wire to the negative battery terminal. Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet. If the reading is less than the specified amount, the leads are bad and the magnet should be replaced.

Individual Brake Magnet Amperage Specifications

Testing Individual Brake Magnet for a Short

To determine if a brake magnet has an internal short, touch the base of the brake magnet to the negative post of a 12-volt battery. Then, connect one of the brake magnet wires to the negative lead of a multimeter and the positive lead of the multimeter to the positive post of the battery. If any amperage is detected, the magnet is shorted and will need to be replaced.

Testing Brake Magnet Resistance

Further testing can be done with an ohmmeter. Using the ohmmeter function on the multimeter, check the resistance between the brake magnet wires. If the resistance is not within the specified range (see specifications below), then the magnet will need to be replaced.

Brake Magnet Resistance Specifications

Troubleshooting electrical brakes

Testing Trailer Brake Magnets for Proper Function

There are 4 different tests that can be done to check the brake magnets on your trailer. The first test you should do is to use a multimeter to check the amperage of your trailer braking system. The trailer brake magnets will draw amperage from the brake controller based on the output voltage sent by the brake controller. Performing this test will let you know if the magnets are functioning properly or if further testing is required.

If further testing is indicated, you can test the individual brake magnets for proper amperage. Test each magnet for a short and test the magnets for resistance. Below we have outlined each of these tests for you.

Testing with Trailer Connected to the Vehicle

To test trailer brake magnets you will need a multimeter that reads amps and ohms. A good brake controller, like theTekonsha P3, has test functions built in. To test with a multimeter, first you will connect the ammeter inline with the blue wire exiting the back of the brake controller or use the brake controller's diagnostic readings.

Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet or magnets. If the reading is less than the specified amount, the leads are bad and the magnet or magnets should be replaced.

Electromagnet Specifications

10 and 12 Inch Brake DrumsMax Amps at 12-13 Volts2 Brakes7.5-8.24 Brakes15.0-16.36 Brakes22.6-24.5

7 inch Diameter Brake DrumMax Amps at 12-13 Volts2 Brakes6.3-6.84 Brakes12.6-13.76 Brakes19.0-20.6

Testing Individual Brake Magnets

Testing individual brake magnets for proper function can be accomplished by severing the magnet wires and connecting the ammeter between the positive terminal of a 12-volt battery and one of the magnet wires; it does not matter which one. Then connect the other magnet wire to the negative battery terminal. Check the amperage. If the amperage is greater than the specified amount (see specifications below), replace the magnet. If the reading is less than the specified amount, the leads are bad and the magnet should be replaced.

Individual Brake Magnet Amperage Specifications

10 and 12 Inch Brake Magnets7 Inch Brake Magnets3.2-4.0 Max amps at 12-13 volts3.0-3.2 Max amps at 12-13 volts

Testing Individual Brake Magnet for a Short

Testing Brake Magnet Resistance

Brake Magnet Resistance Specifications

10 and 12 Inch Brake Magnets7 Inch Brake Magnets3.0-3.8 Ohms3.8-4.0 Ohms