leaking remote oil filter hose

skennelly

Member Posts: 2,196 ✭✭✭✭

skennelly

Member Posts: 2,196 ✭✭✭✭

In prep for the up and coming season I have a small leak coming from a remote oil filter hose...that I plan to address.

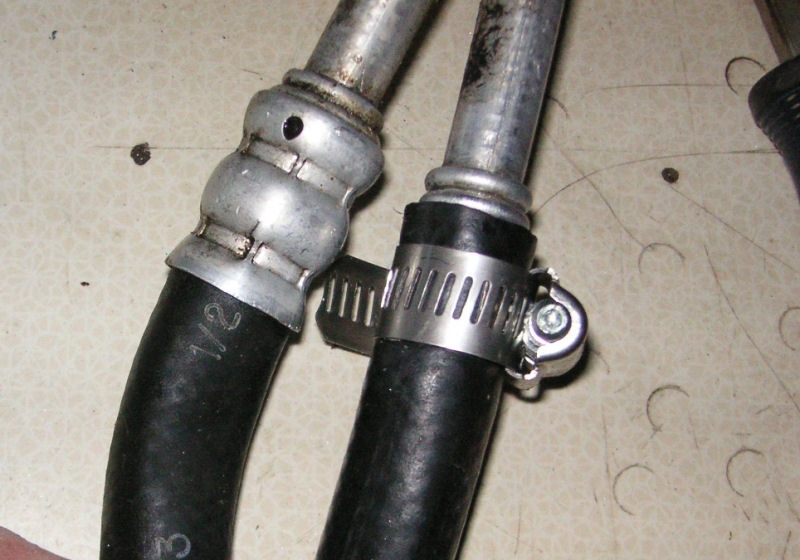

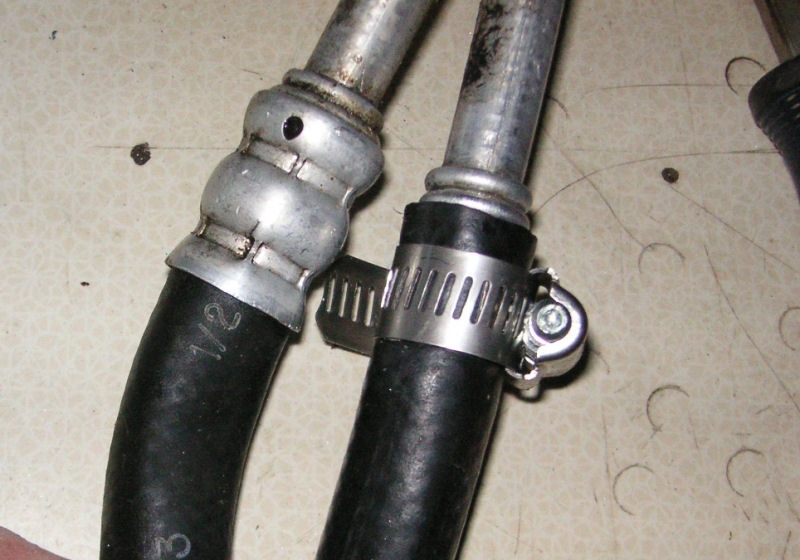

Is this a really bad idea in the picture? Just cut off that crimp and use a hose clamp to secure the hose?

BTW - this isn't something I have done yet...just saw this fix on the internet. I would also use fuel injection hose type clamps that don't cut into the hose when you tighten them.

Is this a really bad idea in the picture? Just cut off that crimp and use a hose clamp to secure the hose?

BTW - this isn't something I have done yet...just saw this fix on the internet. I would also use fuel injection hose type clamps that don't cut into the hose when you tighten them.

2002 - 270FV Mag 350 B3

Comments

so- as with tradition, I too use double clamps whenever possible... breaking tradition, I use different styles- one would certainly be as you said, a fuel injection type band, and the other a constant tension type (kind you need pliers to remove/install). the FI clamp goes between the hose connection and the constant tension. the real pressure is on the constant tension, which will increase its tension with pressure, heat, and resistance, where as the FI clamp will back it up and ensure good seat on cool connections- this way provides that, plus the short run in between the two clamps should remain unstressed.

"the FI clamp goes between the hose connection and the constant tension"

So from the barb end I would first have a FI clamp and then a contact tension clamp?

it's likely not needed, but feeds my OCD with such matters sufficiently. the two clamps operate in different manners- the FI clamp clamps in a static manner- which promotes tearing of the hose in the event of an over pressurization (which is NOT likely to happen in engine oil circuits), and the second clamp (constant tension) is more dynamic, and more forgiving to matters of heat, pressure, resistance- clamping tighter the more volatile the situation, while never cutting into the hose (reducing it's ability to clamp 'cold').

the concept is for the FI clamp to dang near adhere the hose to the fitting- disallowing seepage when cold. the constant tension clamp will absorb any operational expansion/impact under use/load and temperature, and protecting the FI clamp.

i've ran into some situations that this was required, but it isn't common. no matter, though, it's a fine idea for any connection of this sort.

Look close at 3/4" hose. this is on an eberspacher on my truck, and the coolant lines to it- when it's cold (and I mean cold- well below 0) the line contracts and will want to seep... the band clamp (I know, I need a clamp that doesn't cut) seals it tight. after it's being used a while and builds some pressure/temperature- the constant tension takes the load off of it.

2022 Cherokee 294GEBG Black Label land yacht.

Go Steelers!!!

@BellevilleMXZ - My thoughts are a clamp has just as good a chance as a crimp for leaking. I've read stories of crimp hoses blowing off.

https://www.mercurymarine.com/en/us/parts-and-accessories/parts-catalog

The part numbers for mine are 864924 and 864925.

https://www.wholesalemarine.com/oil-line-mercury-mercruiser-32-864924.html

https://www.amazon.com/Mercury-Mercruiser-Quicksilver-32-864925-Line-Oil/dp/B00N9HLJKQ

2022 Cherokee 294GEBG Black Label land yacht.

Go Steelers!!!